Issues with Ex d barriers Glands – Australian EEHA

I don’t think there is a single international supplier of Hazardous Area electrical packages to the Australian Oil and Gas industry who hasn’t been affected in some way by the issue of Ex d barrier gland compliance. Australian EEHA inspectors are known for their laser like focus on the use and installation of Ex d barrier glands, often to the shock and dismay of the international equipment supplier. If you need more information on the function of Ex d barrier glands it can be found on a previous Lithium Oil and Gas Post in the link below:

Do Ex d barrier glands prevent flame propagation or gas migration?

So which Australian standard states exactly how an Ex d barrier gland should be terminated and installed?

AS/NZS 60079.14 is the standard that details in what circumstances an Ex d barrier gland is required, however this standard is light on detail when it comes to explaining exactly how a cable gland should be installed. And if you go searching through other standards you soon find there is limited information. These is some installation guidance which includes information on:

- The use of sealing washers,

- The use of suitable greases,

- Thread engagement,

- Tightness of tapered threads,

- The use of adapters,

- Requirements for glands to only be able to be dismantled by a tool after installation,

- Cable routing to prevent excess tension on the seal around the cable,

- Coldflow characteristics, etc

So, does this mean it’s up to the installer to figure out the rest? No, both AS/NZS 60079.14:2022 and AS/NZS 3000:2018 on multiple occasions make reference to the fact that the electrical equipment must be installed as per the manufacturer’s instructions. So any area not addressed by the standards is usually addressed by the manufacturer’s instructions. If you find that neither the manufacturer’s instructions or the Australian standards contain the details you require it is always worth while contacting a technical representative from the gland manufacturer for further clarification.

So what are the common compliance issues detected?

Before we list common issues detected by Australian EEHA inspectors it is important to note that there are occasions where gland installations have been deemed non-compliant by EEHA inspectors which in fact are compliant. Lithium Oil and Gas recognises that some compliance myths still circulate in our industry and are the first to point out that just because something doesn’t look neat doesn’t mean its non-compliant.

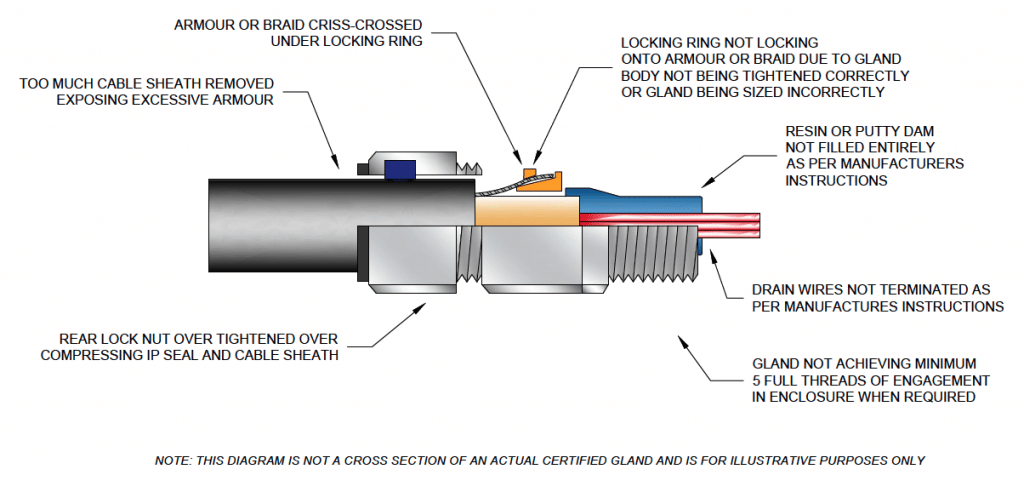

Below is a list of common Ex d barrier gland issues Australian EEHA inspectors commonly identify, this list is not exhaustive but covers common issues:

- The locking ring not locking onto the armour or braid due to gland body not being tightened correctly or the gland not being sized correctly based on the armour thickness.

- Armour locking rings being installed back to front to lock onto the armour or braid better – (some manufacturers have reversible locking rings, but this is not the cases for all glands).

- Resin or putty dam not filled entirely as per manufacturer’s instructions.

- Rear lock nut over tightened over compressing the IP seal and cable sheath.

- Too much cable sheath removed exposing excessive armour.

- Armour or braid criss-crossed under locking ring.

- Resin or putty not being mixed correctly prior to installation.

- Resin or putty being past its used by date prior to use.

- Drain wires on instrumentation cable not being installed and terminated into the resin or putty in accordance with the manufacturer’s instructions.

- Parallel threads not achieving minimum 5 full threads of engagement into the enclosure, or NPT and parallel threads not identified and installed into the wrong enclosure entry types.

“This information represents an opinion only of a general nature, the specifics of each individual situation must be taken into account with reference to the relevant Legislation, Codes of Practice and Australian Standards. Lithium Oil and Gas should be contacted for professional advice if there is any doubt.”